SLA 3D Printer

SLA(Stereolithography) is an additive manufacturing process that works by focusing an UV laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer aided design(CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. This process is repeated for each layer of the design until the 3D object is complete

ZRapid is the innovator of SLA 3D printing, the technology,process and method ZRapid using are now becoming the standard of the whole 3D printing industry.

- 355nm laser

- Fast galvanometer

- iSLA Control System

| Materials: | ZR680( Accurate & White ) ZR710( Tough & White ) ZR820( High Transparency ) |

KEY FEATURES

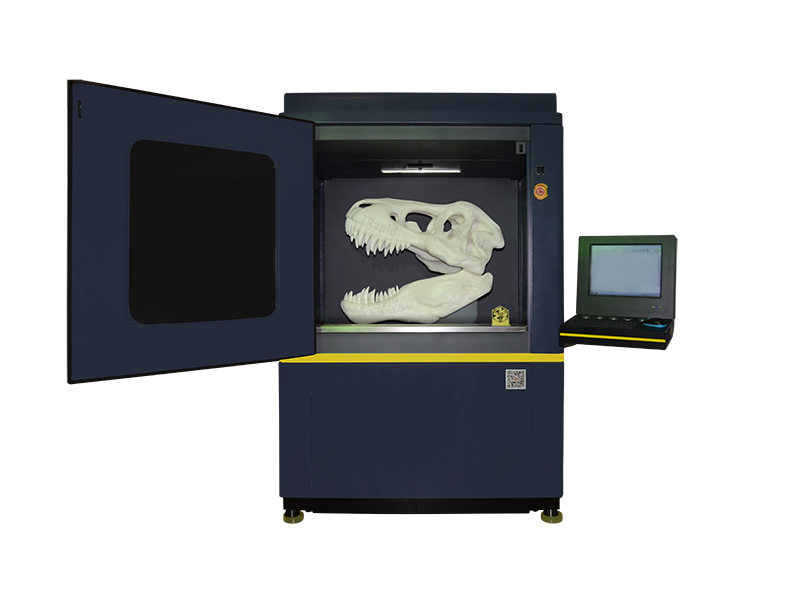

High speed · High precision · High quality

- Fine detail and smooth surface finishing

- Print intricate details with accuracy achievable up to 0.05mm

- Parts can be printed within minutes to hours according to the size and complexity

- Complex structure parts and assembly parts can be printed

- Tough, precise, colorful, pure and heat resistant resin available

- Miscellaneous product range, including iSLA1900D、iSLA1600D、iSLA1300D、iSLA1100D、iSLA1100、iSLA880、iSLA660、iSLA550、iSLA450、iSLA300、iSLA660Lite、iSLA550Lite、iSLA6036、iSLA550Ex

-

iSLA1900D Specifications

LASER SYSTEM

Number of LaserDual Laser

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer (Dual galvanometer)

Parts Scanning Speed6.0~20.0m/s (recommended)

Blank Jumping Speed20.0~40.0m/s (recommended)

Reference Building Speed150~500g/h(Super ×2 / Dual Laser)

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 1825L@800mm(Z)

XY Platform1900mm(X)×1000mm(Y)

Z Axis800mm(standard) / <800mm(custom)

Max Weight150kg@600mm(Z)

Resin heated stylePrecision resistor heater

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 20Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size2.90m(W)×1.70m(D)×2.95m(H)(Operating computer is not included)

WeightApprox. 3500kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

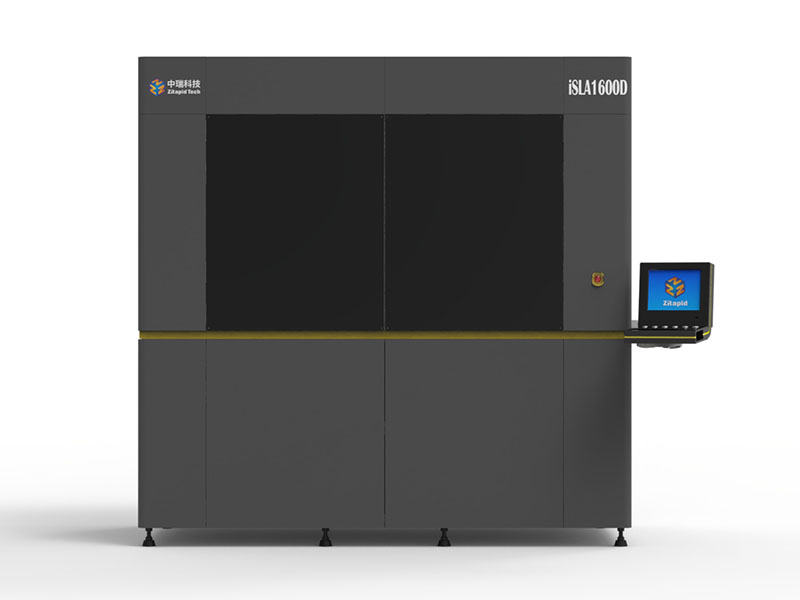

iSLA1600D Specifications

LASER SYSTEM

Number of LaserDual Laser

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer (Dual galvanometer)

Parts Scanning Speed6.0~20.0m/s (recommended)

Blank Jumping Speed20.0~40.0m/s (recommended)

Reference Building Speed150~450g/h(Super ×2 / Dual Laser)

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 1170L@600mm(Z)

XY Platform1600mm(X)×800mm(Y)

Z Axis600mm(standard) / <600mm(custom)

Max Weight150kg@600mm(Z)

Resin heated stylePrecision resistor heater

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 17Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size2.55m(W)×1.60m(D)×2.45m(H)(Operating computer is not included)

WeightApprox. 2600kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA1300D Specifications

LASER SYSTEM

Number of LaserDual Laser

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer (Dual galvanometer)

Parts Scanning Speed6.0~20.0m/s (recommended)

Blank Jumping Speed20.0~40.0m/s (recommended)

Reference Building Speed150~400g/h(Super ×2 / Dual Laser)

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 800L@600mm(Z)

Build Space1300mm(X)×750mm(Y)×600mm(Z)

Max Weight140kg@600mm(Z)

Resin heated stylePrecision resistor heater

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 17Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.85m(W)×1.70m(D)×2.30m(H)(Operating computer is not included)

WeightApprox. 2200kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA1100D Specifications

LASER SYSTEM

Number of LaserDual Laser

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed 150~350g/h(Super ×2 / Dual Laser)ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

Volume785L@600mm(Z)

XY Platform1000mm(X)×1000mm(Y)

Z Axis600mm(standard) ≤ 600mm(custom)

Max Weight120kg@600mm(Z)

Resin heated stylePrecision resistor heater

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 17Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.60m(W)×1.90m(D)×2.30m(H)(Operating computer is not included)

WeightApprox. 1700kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA1100 Specifications

LASER SYSTEM

Number of LaserSole Laser

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed 100~230g/hELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

Volume785L@600mm(Z)

XY Platform1000mm(X)×1000mm(Y)

Z Axis600mm(standard) ≤ 600mm(custom)

Max Weight120kg@600mm(Z)

Resin heated stylePrecision resistor heater

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 17Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.60m(W)×1.90m(D)×2.30m(H)(Operating computer is not included)

WeightApprox. 1700kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

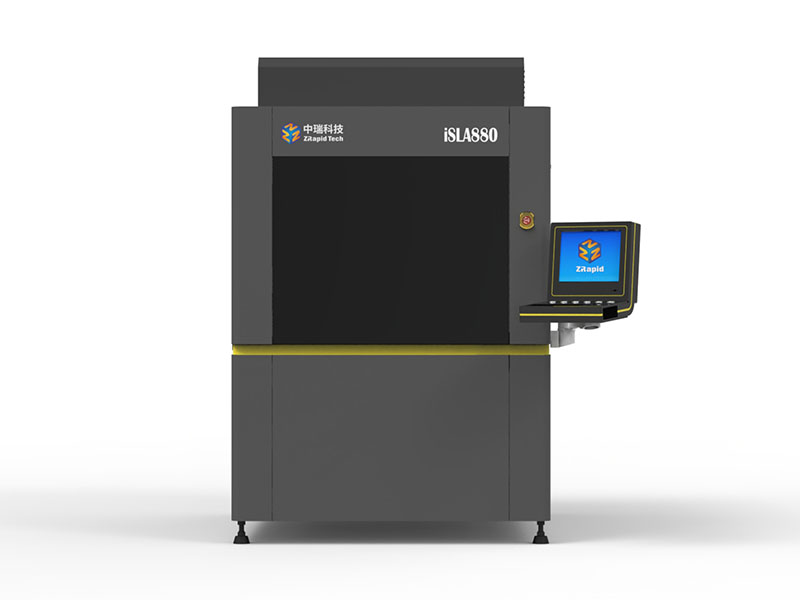

iSLA880 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.16mm(Normal) 0.10~0.50mm(Super)Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed90~220g/h(Super)

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 450L@400mm(Z)

XY Platform800mm(X)×800mm(Y)

Z Axis550mm

Max Weight100kg@400mm(Z)

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.50m(W)×1.40m(D)×2.20m(H)(Operating computer is not included)

WeightApprox. 1000kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA660 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~180 g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

Volume200L@400mm(Z)

XY Platform600mm(X)×600mm(Y)

Z Axis400mm

Max Weight80kg@400mm(Z)

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.60m(W)×1.30m(D)×1.90m(H)

WeightApprox. 900kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

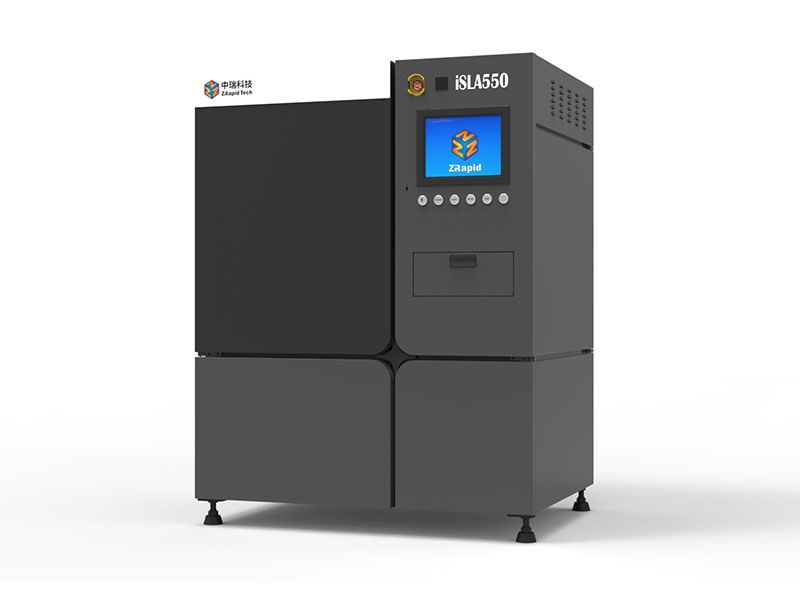

iSLA550 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~140g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 115L@300mm(Z)

XY Platform500mm(X)×500mm(Y)

Z Axis300mm

Max Weight60kg@300mm(Z)

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.45m(W)×1.05m(D)×1.85m(H)

WeightApprox. 820kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA450 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed30~100g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 98L@300mm(Z)

XY Platform450mm(X)×450mm(Y)

Z Axis300mm(standard) 350mm / 400mm(custom)

Max Weight50kg@300mm(Z)

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.45m(W)×1.05m(D)×1.85m(H)

WeightApprox. 820kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

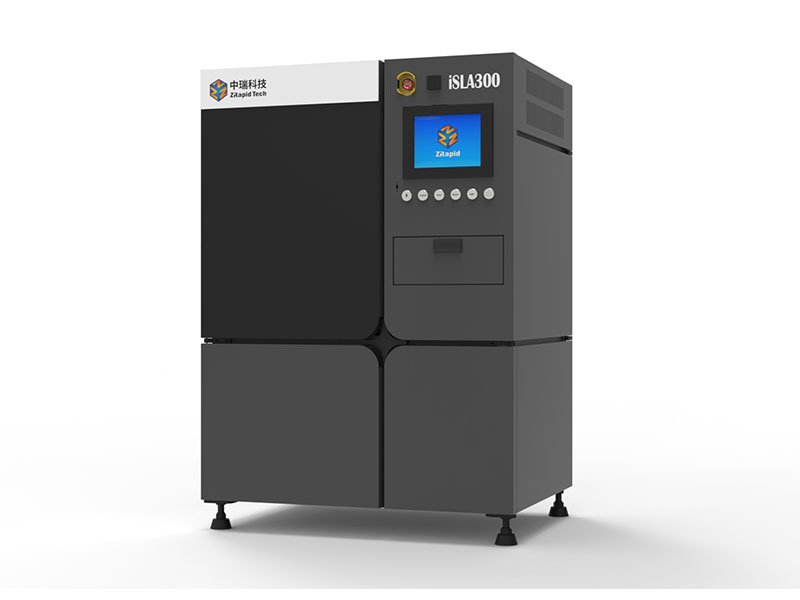

iSLA300 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed30~80g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 42L@200mm(Z)

XY Platform300mm(X)×300mm(Y)

Z Axis200mm

Max Weight30kg@200mm(Z)

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.20m(W)×0.90m(D)×1.70m(H)

WeightApprox. 630kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA660Lite Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~180 g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Stepper Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

Volume200L@400mm(Z)

Build Space600mm(X)×600mm(Y)×400mm(Z)

Max Weight80kg@400mm(Z)

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.20m(W)×1.20m(D)×1.90m(H)(Operating computer is not included)

WeightApprox. 700kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA550Lite Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~140g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Stepper Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 115L@300mm(Z)

Build Space500mm(X)×500mm(Y)×300mm(Z)

Max Weight60kg@300mm(Z)

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.10m(W)×1.10m(D)×1.80m(H)(Operating computer is not included)

WeightApprox. 600kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA6036 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~180 g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Stepper Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

Volume120L@350mm(Z)

XY Platform600mm(X)×360mm(Y)×350mm(Z)

Max Weight60kg@350mm(Z)

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.20m(W)×1.20m(D)×1.90m(H)(Operating computer is not included)

WeightApprox. 700kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract -

iSLA550Ex Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Power1000/2000/3000mW

RECOATING SYSTEM

ProcessIntelligent positioning - Vacuum press recoat

Normal Build0.1mm

Quick Build0.1~0.15mm

Precision Build0.05~0.1mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.10~0.50mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed6.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed50~140g/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 135L@300mm(Z)

Manufacture Size500mm(X)×500mm(Y)×@300mm(Z) ×2

Max Weight60kg ×2

Resin heated styleHot air

Photopolymer ResinSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power200~240VAC 50/60Hz, single phase, 5 / 10Amps

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size2.05m(W)×1.20m(D)×1.90m(H)(Operating computer is not included)

WeightApprox. 1500kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract