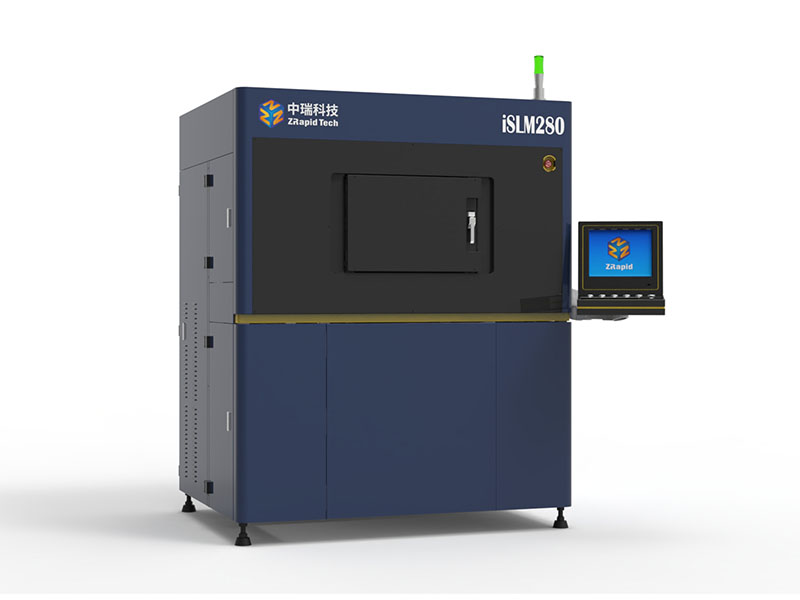

Selective Laser Sintering (SLS)

The selective laser sintering technology uses a CO₂ laser to sinter (fuse) a variety of thermoplastic and metal powders to "grow" 3D objects layer-by-layer from 3D electronic data (STL files). Because this is an additive process, highly complex geometries can be built without issue, and because the powder holds the parts, no support structures have to be added and removed. The key advantage of laser sintering is its ability to rapidly produce durable, functional objects for a wide variety of applications.

- Working parts and assemblies with good detail and surface finishing

- Variety of materials: rigid and flexible plastics, fully dense metal, rubber-like elastomer, foundry-friendly patterns

- Capable of living hinges, high-flex snaps, high stress and heat tolerance and service as short-run tooling

- Can be finished and painted for presentation, demonstration and video reproduction

- Dimensional tolerance within thousandths of an inch

- Delivery of most parts and patterns in just a few working days